PP PE Rigid Regrinds Washing Line

Discover the step-by-step process of washing PP PE rigid regrinds in our detailed video, featuring advanced cleaning and drying systems.

Rumtoo is leading manufacturer of high quality PET Bottle、PP/PE Film Recycling Machinery Rumtoo: Production-ready. Discover how our advanced plastic recycling machines can revolutionize waste management and create a sustainable future.

Features

One of the most advanced and comprehensive recycling machine setups currently on the market.

A fully integrated series of machines designed to process PP / PE films and other plastics seamlessly, ensuring efficient operation and high-quality output from dirty film to pellet form.

High-efficiency components from debalers to pelletizers are ready for deployment in a range of settings from small production facilities to large-scale recycling plants.

Machines are built to handle and automate the cleaning, drying, and repurposing of plastic waste, adhering to the best environmental practices and highest operational standards.

Innovations like our wet granulators and friction washers increase throughput and improve the purity of recycled material, crucial for high-quality end products.

Each setup is designed not just for operational efficiency but also with an eye towards reducing environmental impact, fostering a sustainable recycling process.

Offering fully customizable lines tailored to meet specific needs regarding input capacity, types of plastics processed, and desired output purity.

Inside template

Our PE film washing line offers an input capacity from 500kg/h up to 3,000kg/h, turning dirty PP/PE films into clean, contaminant-free pieces ready for pelletizing.

Our robust shredders, designed for heavy-duty applications, can handle a wide range of materials including plastic film bales, tires, and rigid plastics, with capacities up to 2,000 KG/H.

Our separation equipment, including air classifiers and sink/float tanks, efficiently remove contaminants and sort mixed plastics, crucial for producing high-quality recycled materials.

We offer tailor-made washing lines for various plastics, including PE films and PET bottles, designed to meet your specific capacity and quality requirements.

Our granulators and shredders, featuring high-quality D2 steel blades, ensure consistent and efficient size reduction for various plastic materials.

From dewatering machines to thermal dryers, our equipment ensures thorough cleaning and drying of recycled plastics, preparing them for high-quality output.

Our single and twin-screw extruders, featuring Heat Wave Stabilizing Technology™, produce consistent, high-quality plastic pellets for various applications.

Our state-of-the-art machines ensure that your recycling line operates smoothly, reducing downtime and increasing throughput for maximum profitability.

Ensure your website stays aligned with the latest trends and technologies through regular updates and enhancements.

Our machines integrate effortlessly with your existing systems, ensuring smooth and efficient operations across your entire plant.

Stay ahead of the competition with machines that adapt to new recycling challenges through regular updates and enhancements, supported by our dedicated customer service team.

Step 1: Consultation

Connect with our experts to discuss your specific recycling needs and requirements.

Step 2: Custom Design

Our engineers will create a tailored solution to fit your facility and production goals.

Step 3: Implementation

We'll handle the installation, setup, and training to get your plant operational quickly.

Ready!

Components

Provides frequently used components for building websites using Tailwind CSS

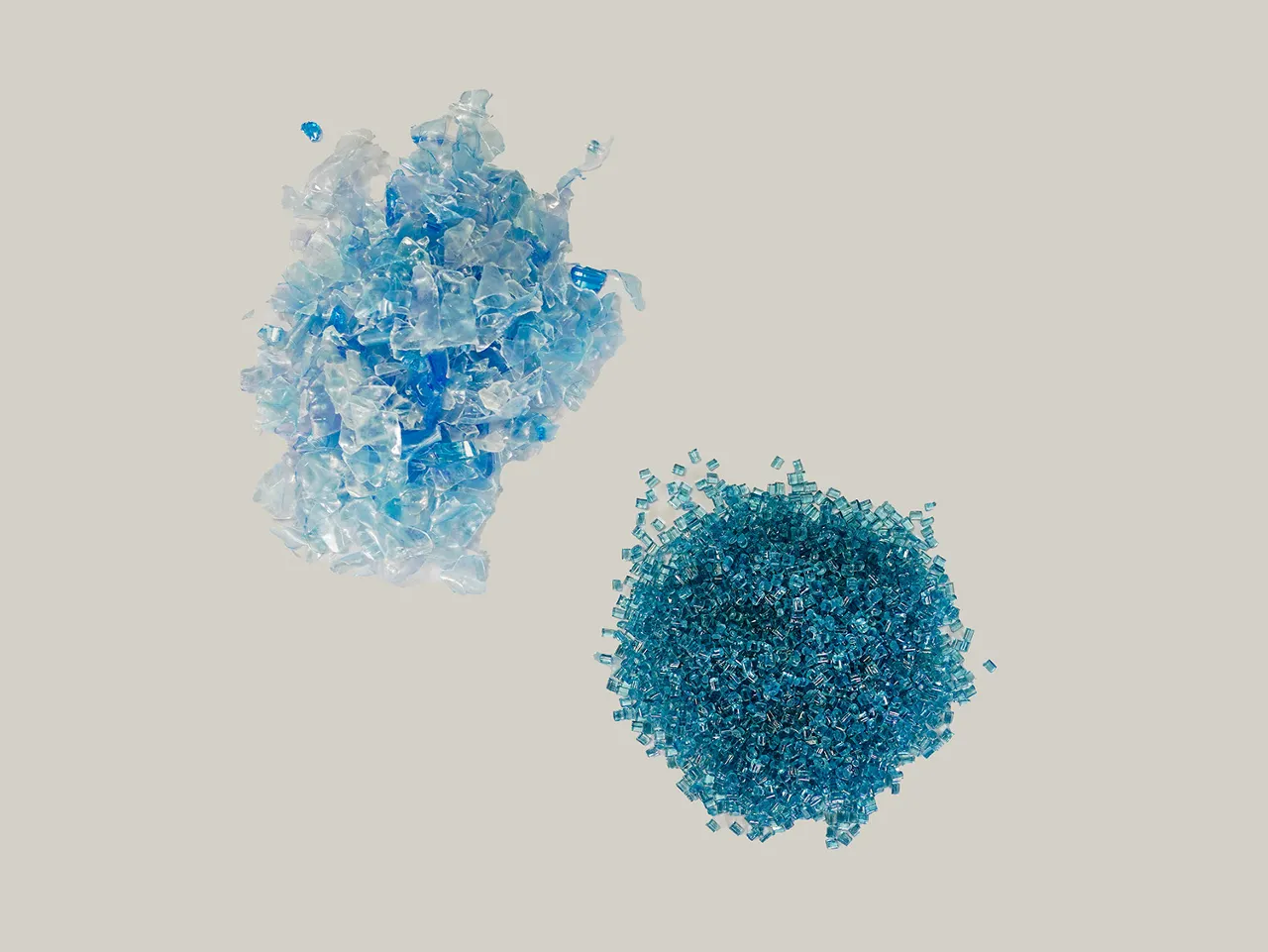

PET bottle pellets are created after the recycling and pelletizing process of used PET bottles. These light blue transparent flakes and dark blue uniform pellets can be used to manufacture new bottles, textiles, or other products, giving old PET a new life.

Artificial turf pellets are produced from recycled synthetic grass fibers, often found in sports fields or landscaping. The green fibers are shredded, processed, and converted into uniform green pellets, which are then used in various plastic products, promoting sustainability.

Rigid plastic waste, characterized by its durable and non-flexible nature, is ideal for high-capacity shredding. From broken toys to household containers, this material is easily recyclable and widely used in various industries after processing.

Waste PE films, commonly found in packaging and agricultural applications, are a staple in the recycling industry. After cleaning and shredding, these films are reintroduced into the market as new plastic products, reducing landfill waste.

Densified materials, formed from compressed waste plastics, are perfect for efficient storage and transportation. Their compact nature makes them ideal for industries looking to minimize space while maximizing material utility.

PVC pipes, often used in construction and plumbing, can be recycled into new pipes or converted into pellets for various plastic products. The recycling of PVC helps reduce environmental impact and promotes the reuse of valuable materials.

Rubber waste, from old tires to discarded industrial materials, finds new life through shredding and reprocessing. Recycled rubber is commonly used in playground surfaces, sports tracks, and other durable, resilient products.

Non-woven fabric waste, often found in disposable items like surgical masks and cleaning wipes, is a significant contributor to plastic pollution. Through recycling, these materials are transformed into new products, helping reduce environmental waste.

Removing labels from PET bottles is an essential step in the recycling process. Clean, label-free PET bottles are processed into flakes or pellets, which can be reused in manufacturing new plastic products like fibers, bottles, and packaging materials.

Our blog is dedicated to providing in-depth articles and insights into the world of plastic recycling machinery. From innovative technologies to detailed guides, each post offers valuable information to help you enhance your recycling processes and stay updated with the latest industry trends. Explore expert tips, case studies, and machinery features designed to improve efficiency and sustainability in your operations.

Discover the step-by-step process of washing PP PE rigid regrinds in our detailed video, featuring advanced cleaning and drying systems.

Discover how a granulator for PET flakes can enhance recycling efficiency and material quality. Learn about its mechanics, benefits, and optimal designs.

Discover the intricate challenges of PVC contamination in PET bottle recycling and learn practical solutions to produce high-quality PET flakes.

Explore vital tools and resources for a sleek website. From design to functionality, our guide elevates your online presence.

FAQs

Dive into the following questions to gain insights into the powerful features that Rumtoo Recycling offers and how it can elevate your plastic recycling operations.

Rumtoo Recycling has over two decades of experience in manufacturing plastic recycling machinery. We are committed to producing high-quality, durable equipment and providing excellent customer service and after-sales support. Our machinery is rigorously tested to ensure stability and reliability in long-term use.

We offer installation services, including arranging Rumtoo-certified electrical and mechanical engineers to assist with equipment installation and commissioning. The installation process typically takes 7 to 14 days, depending on the size of the project.

First, contact our sales team to discuss your equipment needs in detail. Once the specifications are confirmed, we will provide a detailed quotation and sign a contract. The usual production period is 60 days. All equipment is tested before shipment, and we recommend customers visit our factory for inspection.

Yes, our machines can pass CE or ISO9001:2000 certification, ensuring quality and safety.

We offer a one-year quality warranty on all our equipment. If any manufacturing defects are found within the warranty period, we will provide replacement parts free of charge.

We welcome you to contact our customer service team via email or phone at any time. We are dedicated to answering any questions and providing the support you need.

If you have any questions regarding our ordering procedures.

feel free to contact us at anytime