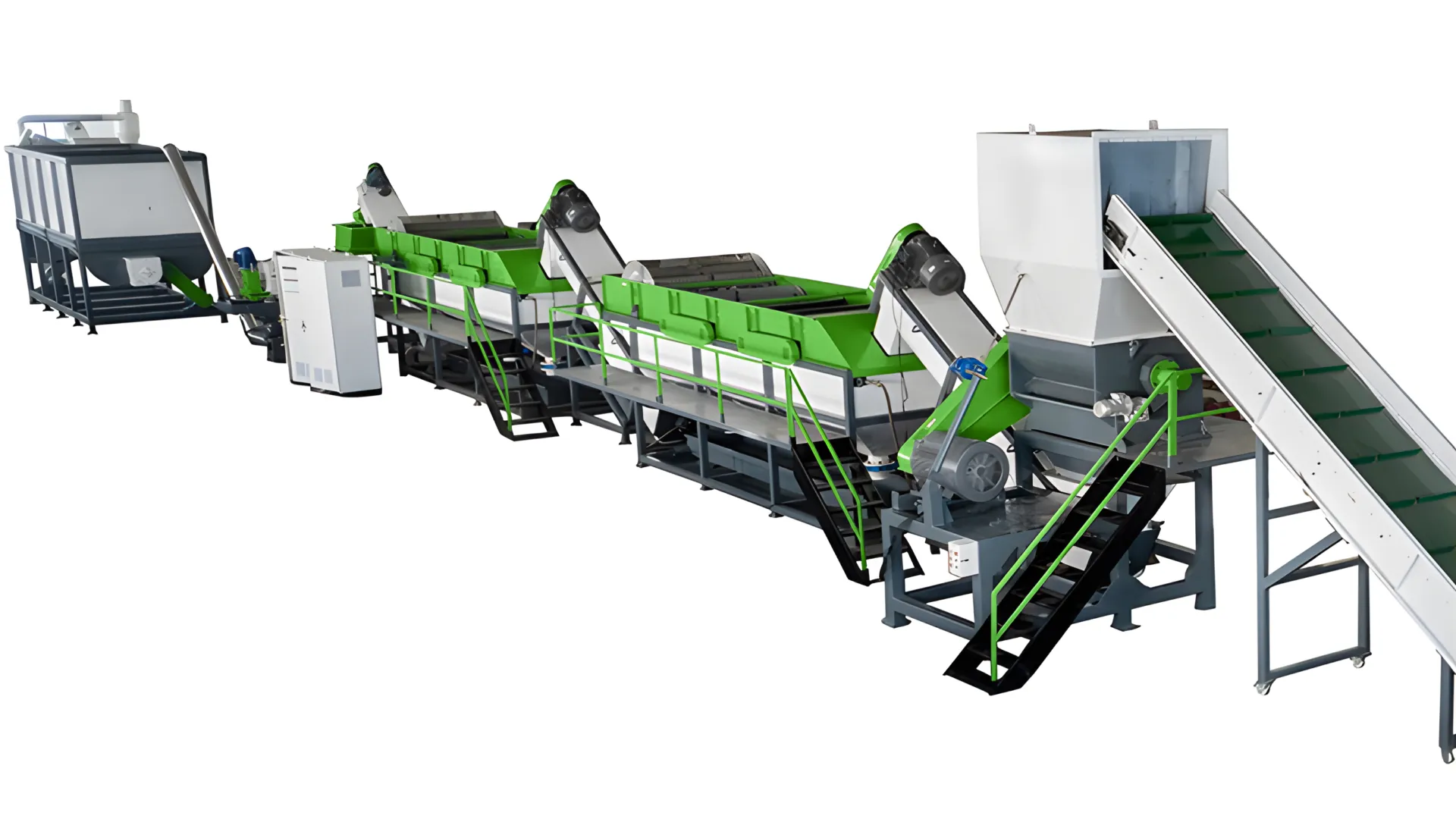

Rigid Plastic Recycling Lines

Efficient Recycling Solutions for HDPE, PP, and PS Plastics

Our rigid plastic recycling plant offers a quick and easy solution for recycling dirty rigid plastics such as HDPE bottles, pipes, and more. With capacities ranging from 500 kg/hr to 2000 kg/hr, our solutions are customizable to meet your needs.

Working Principle

Explore how our recycling lines work to efficiently process rigid plastics.

Bale Breaker

Opens bales of input material to ensure smooth and continuous material flow.

Plastic Shredder

Shreds bulky plastic into large pieces, making it easier for further processing.

Plastic Granulator

Further reduces plastic size after shredding for efficient washing and cleaning.

Friction Screw Washer

Cleans and transports materials while removing contaminants.

Sink Float Separation Tank

Separates dirt, rocks, and metals from plastic materials.

Thermal Dryer System

Removes moisture from cleaned plastic, reducing it to below 3%.

Additional Information

PP Regrind

Used in plastic chairs, baskets, and bottle caps due to its durability and strength.

HDPE Regrind

Commonly found in containers, pipes, and bottles for its impact resistance and chemical durability.

PVC Regrind

Used in pipes, window frames, and flooring for its durability and adaptability.

ABS Regrind

Found in automotive parts and electronics housings due to its toughness and surface finish.

PET Regrind

Widely used in bottles and packaging for its strength and clarity, ideal for preserving freshness.

Key Components

Screw Feeder

Conveys and filters materials while cleaning sediment with high durability.

Wet Plastic Granulator

Efficient cutting and pre-cleaning of plastic bottles and rigid materials with customizable blade options.

Friction Washer

Provides thorough cleaning of plastic materials using friction-based cleaning and water.

Floating Separation Tank

Separates PP and PE plastics from contaminants while simultaneously cleaning the materials.

Hot Washer

Removes oils and stubborn contaminants from PET and HDPE flakes through hot chemical baths.

Centrifugal Dryer

Removes moisture from plastic regrinds using high-speed rotation, reducing moisture content by 20-30%.

Thermal Dryer

Uses hot air to remove moisture, reducing it to below 3%, ideal for final processing.

Zig-Zag Air Classifier

Separates lightweight contaminants like labels and provides partial drying for PET bottle recycling lines.

Recycling Process and Output

From raw materials to finished products: See our recycling line in action

Customer Feedback

" Our facility has seen a tremendous increase in efficiency since integrating the rigid plastic recycling lines. The final product quality is consistently high. "

John Doe

Plant Manager

" The customization options allowed us to perfectly fit the recycling lines into our facility's needs. We couldn't be more satisfied with the results. "

Jane Smith

Operations Manager

" The technology and customer support have been outstanding. We've significantly reduced water and energy consumption while increasing output. "

Mark Johnson

Sustainability Director

Upgrade Your Plastic Recycling Today

Ready to take your recycling processes to the next level? Contact us for custom solutions tailored to your needs.